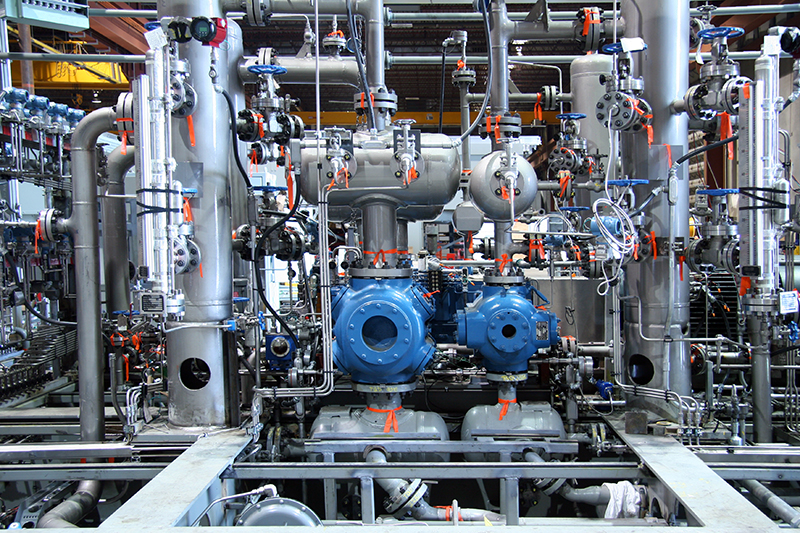

In continuing our commitment to providing a full range of service for our customers, we have recently expanded our portfolio to include compressor component repair. With our many years of experience in remanufacturing, we now offer that same standard of reconditioning quality for compressor components.

Before reconditioning services are rendered, the component pieces are assessed by our resident lead machinists, millwrights and welders. The pieces are then restored to their original specifications in house, for optimal performance.

Our technicians employ an AMC precision boring machine, custom built lapping machine, metalizing system, cylindrical grinder, custom built piston/rod torque bench, Sunnen honing equipment, five engine lathes, three mills, and two hydraulic presses to provide disassembly and reassembly, inspection, machining and re-sizing, lapping, babbiting, bead blasting, quality control testing and replacement to all internal compressor components.

RECONDITIONING SERVICES

Packing cases, piston and rod assemblies, wiper & auxiliary boxes, compressor valves, VVCP assemblies, crossheads, connecting rods, and bushings.

FIELD SERVICES

Vibration analysis, custom design, scheduled maintenance, troubleshooting, and inspection.

Schedule anytime.