We stock complete units and all critical parts for all of the various turbochargers found in the oil and gas industry and are able to service and repair a wide variety of applications, which include the following OEM manufacturers:

Alamo has designed and manufactured many of the premium upgraded components that are in our inventory. This ensures a product that is equal to, and in most cases, superior to the O.E.M. product it replaces. Our philosophy has always been that cost savings to our customers can only come from better products and improved procedures. This is evident in the increased service life of our products, such as our stainless steel nozzle rings, billet regulators and our line of stainless steel exhaust bellows.

In order to address the issue of premature thrust failure, we designed and released an extreme duty upgraded turbocharger for the 3500 series Caterpillar© engine. These units use ball bearing technology and are made of premium grade material, manufactured in North America to ensure superior quality and are available to replace various units found on G3500 series engines.

Alamo Industries Ltd. has been manufacturing regulators for over a decade. We have an extensive in-house quality control program for every step of the manufacturing and assembly process.

All of the A.I.L.™ brand of regulators are a direct OEM replacement and machined from top quality exhaust grade bar stock, with a multiple bolt pattern that fits a wide variety of applications. It is worth noting that none of Alamo's regulator parts use a sand casting process, BILLET ONLY. The added aluminum ribs assist in dissipation of heat.

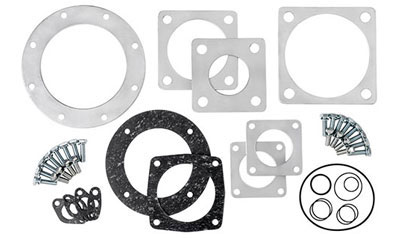

Alamo Industries Ltd. maintains an inventory of the common charge air coolers found in the industry. These units are remanufactured, re-qualified and assembled with new gaskets. All air seams are pressure checked to ensure soundness. We have improved the integrity of the charge air coolers by using higher quality joint washers.

Many of our customers report improved engine operation through reduced charge-air temperatures by servicing their coolers at the same time as the turbocharger.

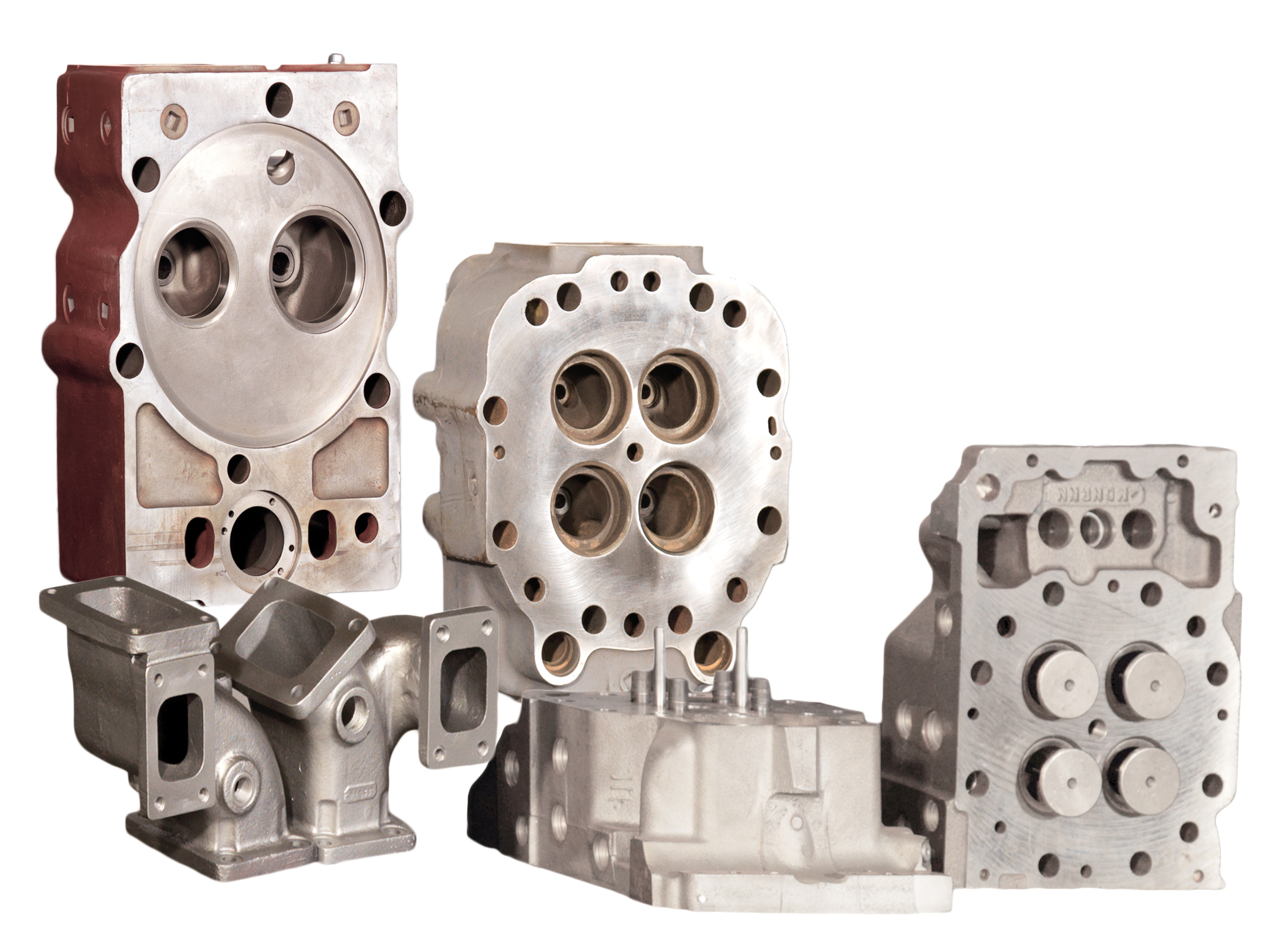

We stock a selection of exhaust manifolds and air filters for the most common engines in the oil industry. These are available on an exchange basis or we can repair your unit in a timely manner, using Engineer certified procedures.

We design, manufacture and stock a wide variety of premium quality expansion joints for the oil and gas industry. Alamo designed many of the expansion joints available and these units are engineered to be vastly superior to existing O.E.M. models. A proper seal to the exhaust drive of the turbocharger improves the efficiency of your unit and saves money. Our prices are competitive and if we sell you a unit, we will keep stock in our inventory.

In keeping with our tradition of product improvement, Alamo Industries Ltd. improved the design for the water jumper on the Superior 825 line of engines. These updated units are a bolt-on replacement for Superior part # A024-998 and will eliminate the safety and environmental problems caused by glycol leaks due to leaking gaskets and cracked castings. Our updated water jumper compensates for the misalignment and movement which occurs between the cylinder block and cylinder heads. They have been extensively field tested and references are available upon request.

Coming Soon.

Alamo can meet your needs for air intake connectors and rubber bellows for most of the common engines found in the industry. This is an often overlooked item and we urge our customers to utilize them to minimize maintenance costs.

Air to the turbocharger is 100% filtered, therefore a leaking connector can suck in dirt and damage your turbocharger. Every cubic inch of air lost costs you money and a leaking connector can be a safety concern.